RD TROCHE MOLDS

10x Your Troche Productivity In 60 Days.

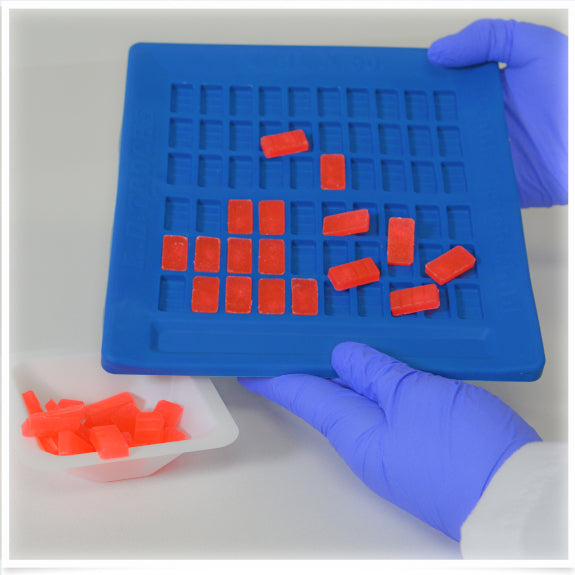

Instead of filling individual troche cavities one-at-a-time, your compounding staff can now fill hundreds of troche lozenges at once.

R.D. Troche Molds are the most convenient way to make troches in your compounding pharmacy. Simply pour and disperse the melted mixture over the mold and cool to reveal vast numbers of newly-formed mini-Troches every day.

Industry Success

Designed for Efficiency

Ranging from 60 to 500 hundred cavities with different cavity sizes, RD Troche Molds are suitable for almost any compounding laboratory.

Made with ultra-high grade heat-resistant thermoplastic elastomers used in urology and surgical sectors, R.D. Troche Molds will outperform steel molds, and outlive other elastomeric molds.

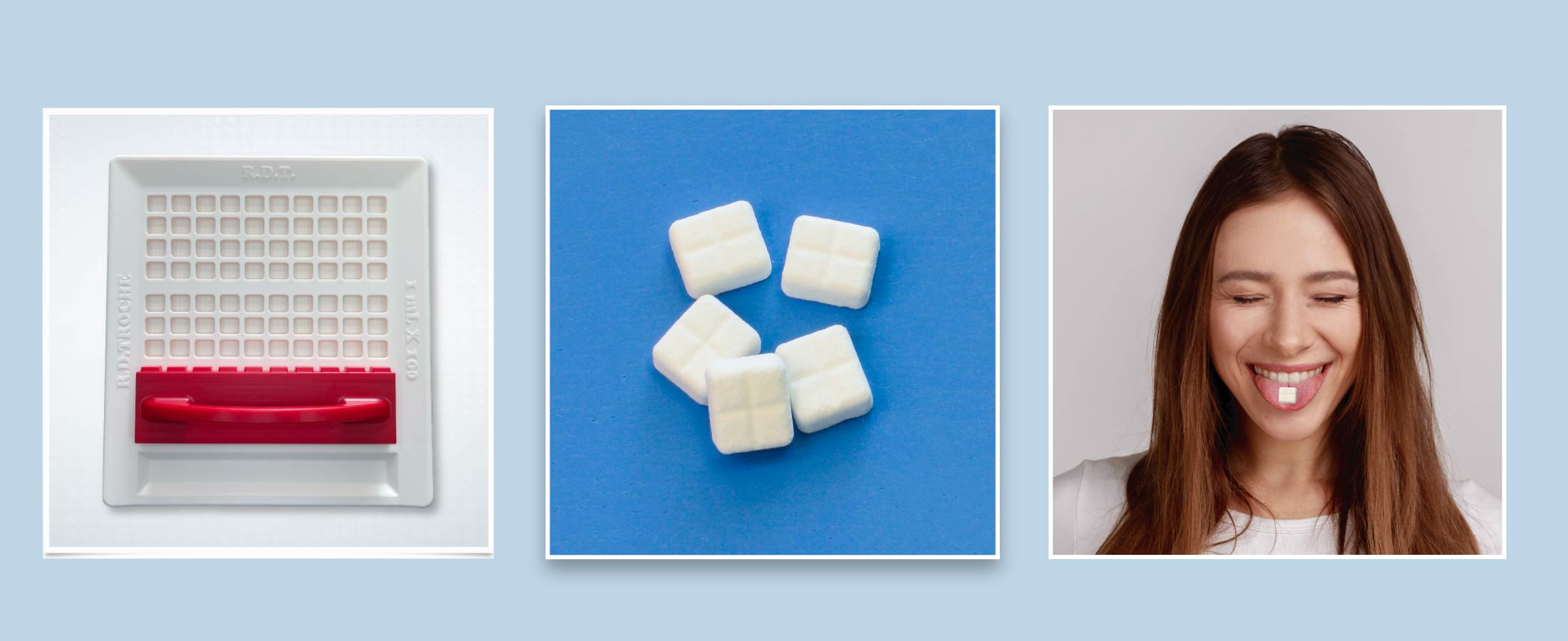

Scored. Comfortable. Ideal.

R.D. Troches are smaller than the average troche, but can still fit the API strengths you need. Smaller troches dissolve faster, making it easier for patients to be compliant. Moreover, each R.D. Troche is scored for patients to easily cut the troche to accommodate custom dosage needs as needed.

The technology is in the material

Compounds and other preparations can be made in just seconds to minutes with all your favorite bases from every compounding wholesaler.

With non-stick coating manufactured into the molds, R.D. Troches are smooth enough to instantly release troches made with most bases from your favorite compounding wholesalers. When the troches are completely cooled and formed, you'll see troches fall out of the mold with almost no effort.

Designed for Efficiency

R.D. Troche Molds CAN improve compounding speed and productivity with incredible durability, effortless scalability, and uncompromised ease-of-use. Your staff doesn't have to fill cavities one at a time, but instead quickly fill as many as your pharmacy needs. Whether it's a unique strength for a specific patient, or it's a large batch of your popular prescriptions, your compounding pharmacy will fill troches like never before.

As a company founded by compounding pharmacists, our philosophy is simple: we innovate and share our success with other pharmacists. Empowering small compounding businesses and companies in growing industries with the necessary compounding technologies to thrive in a competitive environment is our passion.

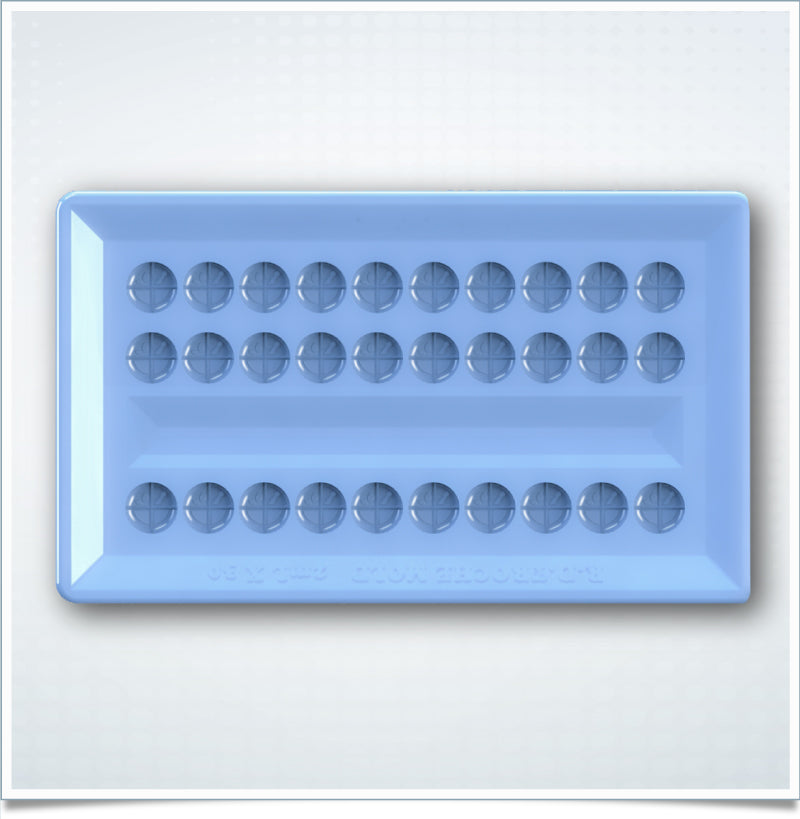

0.25 mL Cavity Mold

One hundred cavities per mold, segmented into groups of 30, 30 and 40

0.25 mL cavity has API capacity of ~75mg

Micro troche design dissolves within minutes

Food-grade silicone mold material is heat resistant up to 302° F (150° C)

Incorporated run-off trough collects excess material

Triple-score design makes it easier for patients to titrate their dosage

- Increased R.D Troche Molds

- Increased 3.5x3.5" Scraping Spatulas

- Formulas + Ongoing Release*

- Formula Conversion Support (limited)

- Marketing Tools

- Referrals

- 30-Days Money Back Guarantee

- One Year Full Warranty

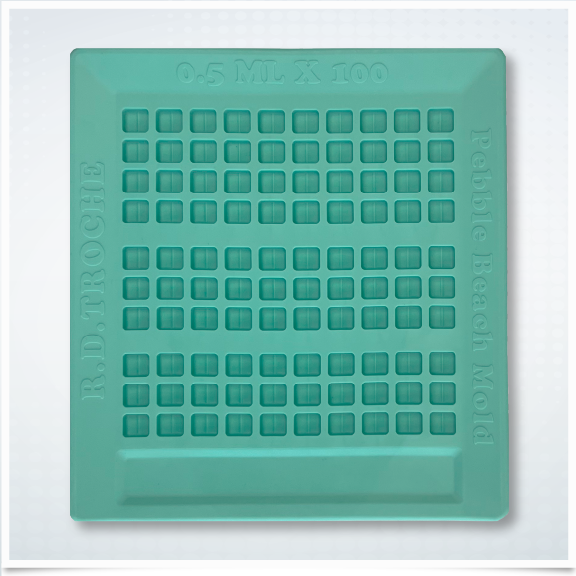

0.5 mL Cavity Mold

One hundred cavities per mold, segmented into groups of 30, 30 and 40

0.48 mL cavity has API capacity of ~140 mg

Small troche design dissolves quickly

Thermoplastic elastomer mold material is heat resistant up to 250° F (121° C)

Incorporated run-off trough collects excess material

Single-score design for patients to control their dosage

- Increased R.D Troche Molds

- Increased 3.5x3.5" Scraping Spatulas

- Formulas + Ongoing Release*

- Formula Conversion Support (limited)

- Marketing Tools

- Referrals

- 30-Days Money Back Guarantee

- One Year Full Warranty

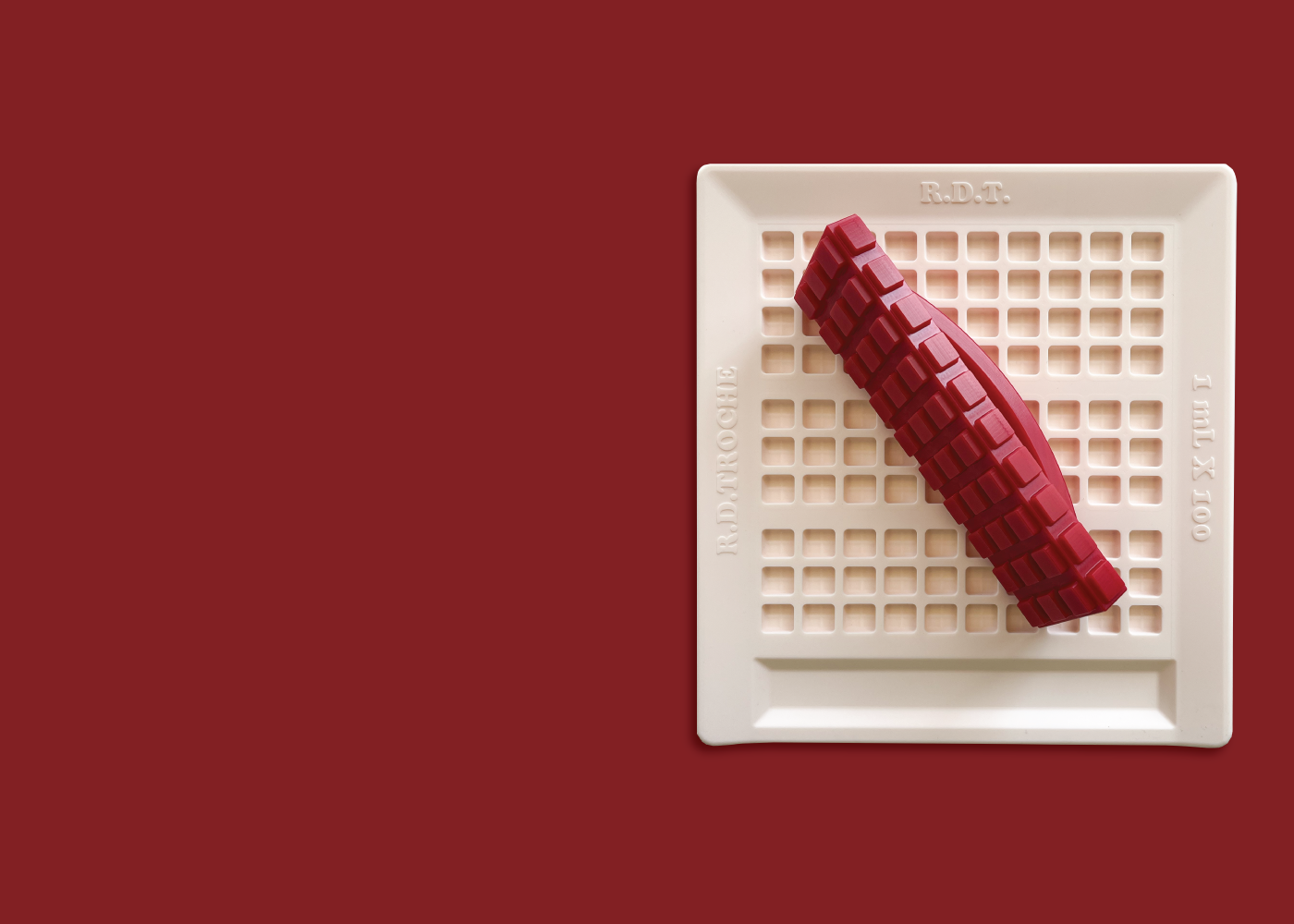

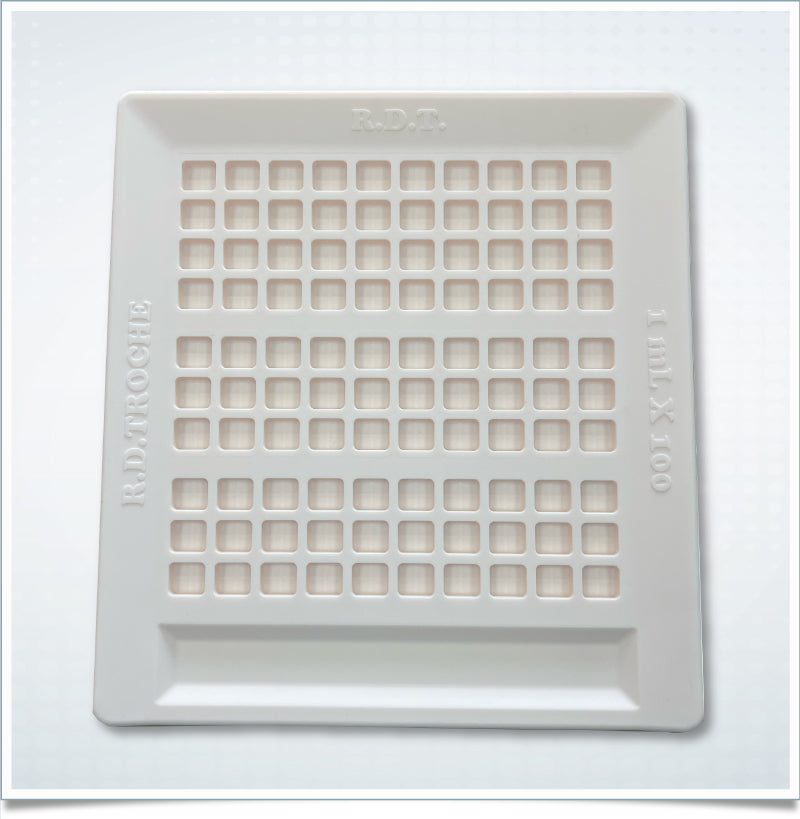

1.0 mL Cavity Mold

Sixty cavities per mold, segmented into groups of 30

1.0 mL cavity has API capacity of ~300 mg

Thin troche design dissolves quickly

Thermoplastic elastomer mold material is heat resistant up to 250° F (121° C)

Incorporated run-off trough collects excess material

Triple-score design makes it easier for patients to titrate their dosage

- Increased R.D Troche Molds

- Increased 3.5x3.5" Scraping Spatulas

- Formulas + Ongoing Release*

- Formula Conversion Support (limited)

- Marketing Tools

- Referrals

- 30-Days Money Back Guarantee

- One Year Full Warranty

0.5 mL x 500 Cavities

Troche Mold Filling

The R.D. TROCHE MOLDS are made from durable, semi-flexible materials for longterm protection against damage, deformation, and heat. 100% reusable and free of lead, cadmium, latex, PVC and other undesirable materials.

Cleaning can be as simple as pouring hot water over the mold, or loading into the top rack of your lab's dishwasher.

Maximize Your Productivity Today!

From start to finish, in a head to head comparison against traditional troche molds (compounding Tadalafil 50mg troches, 100 ct.), the R.D. Troche Molds set a new record for the shortest time to completion.

TICKERWORKS Molding technology allows the smaller compounding pharmacies to easily compete against large compounding facilities.